POWER HACKSAW

Features of power hacksaw

features of a power hacksaw

. correct blade of different types

. features of power hacksaw blade

Cut-off saws are used to cut metal stock roughly to the required length. 🤺 commonly used to cut off saw in small scale industries is a POWER SAW.

|

| Power hacksaw |

Features

The power saw works like a handsaw, and has an arrangement for cutting during the movement in one direction and releasing pressure on the non-cutting stroke. The rotary motion of the motor is converted into linear motion by a crank mechanism.

The required cutting pressure is obtained hydraulically or by an adjustable weight.

During the non-cutting motion the blade will be lifted away from the work.

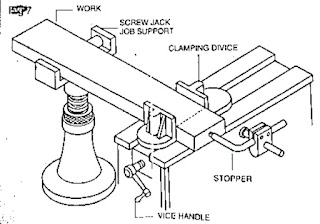

A clamping device /vice holds the work firmly.

Power hacksaw blades

The saw blades are selected, depending on the machine and the type of work on hand. The blades are made of H. S. Steel and are fully hardened.

For different materials, blades of different pitches are used (number of teeth per 25mm length ).

As a general rule, the softer the material, the lesser is the number of teeth, per length of 25mm.

Teeth with a large pitch can accommodate large chips.

Blades are available with varying coarseness i.e between 4 to 14 teeth per 25 mm length.

Coarse pitch blades are also used while cutting large sections of stock, as this will help in greater chip clearance and increased penetration.

For cutting hard material, and thin material, a 14 pitch blade is recommended.

For general purpose sawing, a 10 pitch blade will be useful.

While selecting blades, make sure atleast two teeth of the blade will be in contact with the work at all times.

What will happen if less than two teeth are in contact with the work?

The work can be caught in the tooth gullet, and cause breakage to the blade.

Blade clearance

In order to avoid jamming of the teeth and to provide for chip clearance, the teeth of the saw bladers are offset or waved.

SPECIFICTION OF POWER HACKSAW BLADES

while specifying power hacksaw blades, it is necessary to state

-the length (distance between centre of holes)

-the width

-the thickness and

-the teeth pitch

Clamping arrangement

Power saws are provided with clamping devices similar to those in machine vices, and the work can be gripped by using the crank handle.

When a number of pieces of the same size are to be cut, an adjustable stop is used.

Long bars are supported, and the level maintained by the use of adjustable floor stands.

Fixing blades

The blades are mounted on frames using screws.

The teeth of the blade should point towards correct direction. (Depending on the type of machine the blade either cuts on the forward or on the return stroke).

It is necessary to follow the directions given by the manufactures as indicated in the frame.

Tension the blades using the tensioning device.

Comments

Post a Comment